Machines of Your Imaginations

About Us

Welcome to Mantra Machineries!

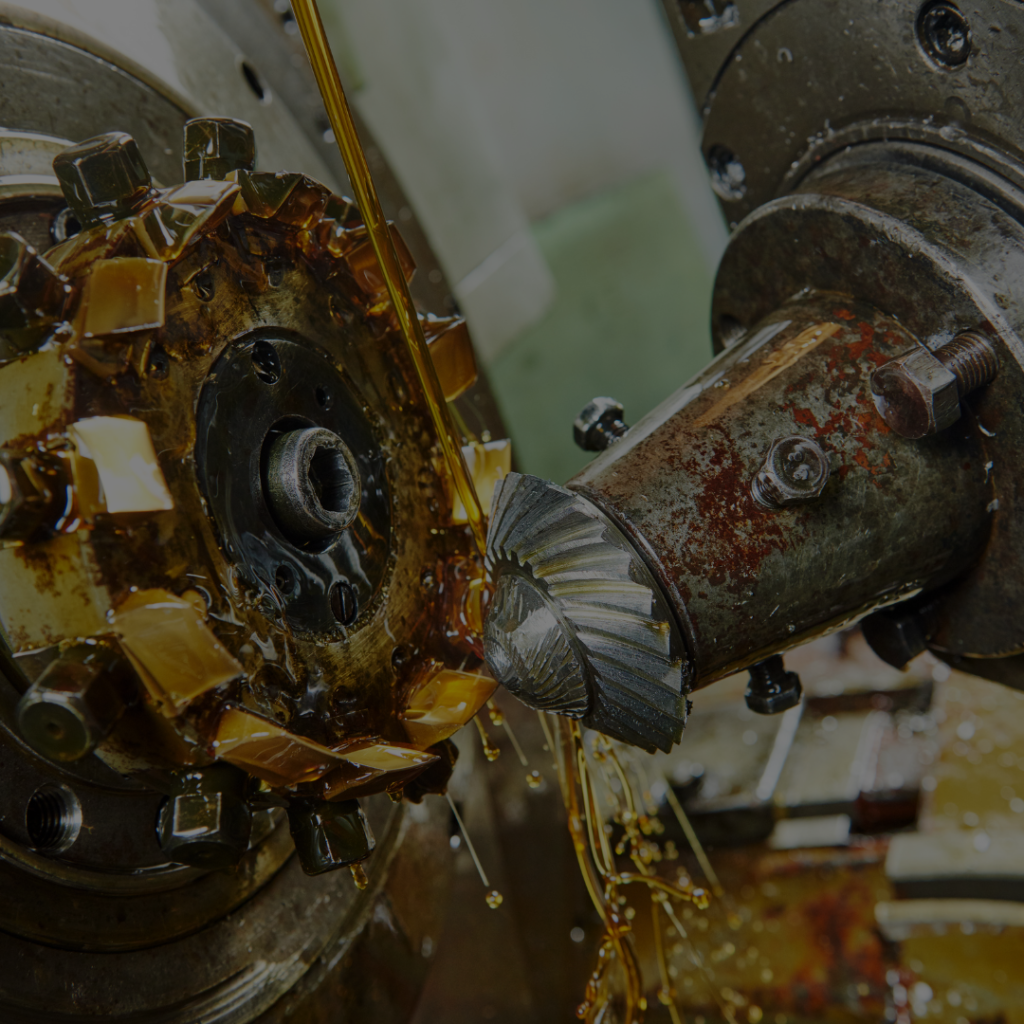

We are a Ghaziabad, India based manufacturer of high-performance Tube Mills and related machineries. We are committed to Precision, Innovation, and Efficiency.

We specialize in the Design, Engineering, and Manufacturing of:

- Cut-to-Length Machines

- Stainless Steel (S. S.) Tube Mills

- ERW Tube Mills

- Slitting Machines

- Shearing Machines

- Bending Machines

and other customized metal forming equipment.

Our machines are engineered for Accuracy, Durability, and Peak Performance, serving industries such as Steel, Construction, Automotive, Agriculture, Sheet Metal, and Fabrication — across India and international markets.

At Mantra Machinery, we also provide Custom Machine Design and Technical Consultation Services to meet our client's Specific Machine Requirements.

Whether you need a complete Cut-to-Length Line or a Tailored Slitting Line, we have complete Sheet Metal Machinery Solutions to boost your Production and enhance its Productivity.

Our Products

Slitting line Machine

Cut to length line Machine

Tubemill

Sheet leveller 6 HI

Services

Custom Machine Design

At Mantra Machineries, we understand that every business has different needs, that’s why we offer Custom Machine Design solutions to address the needs of every client to meet their Requirement and Business Goals. From concept engineering through detailed CAD/CAE Modelling, Prototyping and Final build-out. We work closely with our Clients to turn their requirements into Efficient, Reliable, and Cost-effective Machine Solutions.

Our custom design Services include Special-purpose Machines, Automated Material Handling Systems, Assembly lines and Bespoke Fabrication Equipment.

If you want to enhance your Productivity, improve your Accuracy, reduce your Manual Handling and LOWER your Maintenance costs with Customized Machine Design, Mantra Machineries is your go-to destination.

Manufacturing Consultation

Installation & Commissioning

What this service includes?

- Site Preparation & Foundation check: Verification of Structural and Environmental readiness.

- Mechanical and Electrical Installation: Alignment, Anchoring, Wiring, Sensor & Actuator setup, and Control-system integration.

- Pre-commissioning checks: Mechanical, Electrical, and Functional validations.

- Commissioning & Start-up: Load Performance Tests, Safety Checks, Operator hand-over, and Team training.

- Documentation & Hand-over: Full Reports, Calibration data sharing, Operational training, and Maintenance guidance for long-term operation.

Why does it matter?

Early engagement with your team helps minimize downtime, reduces risks, and ensures optimal performance. Whether you are installing a Single Machine or a Full Production line, our engineered approach ensures Maximum Value and Reliable long-term Operation.

Maintenance & Support

- Preventive & Predictive maintenance: Scheduled inspections, alignment, and calibration to avoid sudden breakdown.

- Commissioning & Operator training We commission each machine carefully and train its operators for hands-on experience and smooth operation from day one.

- Performance audits: We do periodic audits and give recommendations to maximize output and Machine life.

Process Optimization

Process Optimization improves your Production, Uptime, and Product Quality across your Coil-processing and Tube lines. It results in faster Changeovers, reduced scrap, and consistent Tolerances.

- Line audit & Bottleneck analysis (Setup, Material handling, Tooling)

- Machine tuning: Alignment, Roll/ Tool adjustments & PLC parameter optimization

- Changeover reduction & Cycle-time improvements

- Quality controls: Data processing, SPC, and Operator training

- Actionable report with ROI-focused recommendations

Quality Assurance

- Raw material & Supplier credentials

- In-process dimensional checks and NDT (Ultrasonic/ eddy/ current)

- Functional & Load acceptance testing (Factory & Site)

- Calibration, Documentation & Inspection reports

- Operator training and Preventive maintenance guidance

Technology & Integration

- Seamless PLC/HMI and SCADA integration for centralized control and easy operation.

- Servo feeders & Precision motion control for repeatable Feed accuracy and reduced Material wastage.

- Turnkey retrofits, System validation, and Operator training for smooth Commissioning.

What it does?

It helps in faster set-ups, increased production, predictable maintenance, and negligible breakdown.

Training & Education

- Operator Training: Safe start-up, Machine indexing & Quality checks.

- Maintenance modules: Routine care, Fault diagnosis & Calibration.

- Advanced Training: Process optimization, PLC/controls overview, and Digital control.

- Custom & certification tracks for production teams and supervisors.

Tailored training helps you standardize Procedures, cut Setup time, and preserve Machine Life.